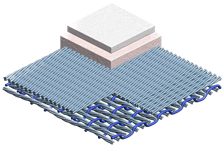

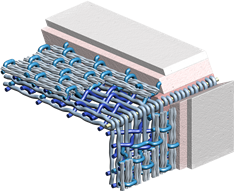

| | MicroplaneTM |  | | DuraseamTM |

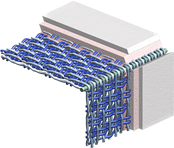

| | MicroseamTM |

Today's pulp and paper makers demand superior performance from press fabrics. A 1% dryness increase exiting the press

section results in 4% less steam consumption in the dryer section or an equivalent increase in speed, thus underlining the importance of proper press felt designs.

Cristini has a wide range of endless and pin seam designs tailored to your application. Cristini pioneered and patented pin-seam technology in the mid 50's (patent n.554352, US 569040) and since that time has developed a wide range of pin-seamed press fabrics made with the lightest base (1250 g/m2) fabrics to the heaviest (2400g/m2) with double seam. For high speed machines (800-1000mpm+) where nip dewatering is a must, Cristini has developed a family of incompressible felts, including the nonwoven base Ventaplane, family. Our impressive references speak for themselves.

Click to Request More Information

Cristini North America Inc.

700 Cristini Blvd

Lachute, QC Canada J8H 4N3

Tel. (450) 562-5511 / 1-800-720-2002

Fax (450) 562-5055

Email: sales@cristini.com

|

|

|

DID YOU KNOW ??

- The FiberScan Fix system has helped mills save hundreds of thousands through efficiency increases and energy conservation

- Cristini is the preferred supplier for PMC and instrumentation on the world's fastest packaging grade machines

- Cristini's DuraseamTM Press Felt Technology is the industry's most durable pin seam afterall Cristini invented the Pin seam in the 1950's

- Cristini's Maxiflyer SSB Fabrics are proven to improve printability and fiber retention

- MaxDry Spiral Fabrics have the industry's largest yarns = 30% more wear Potential

- Cristini HiLife Carrier rope continuously outperforms the competition in every position but for those extra difficult applications Tuffbraid brings an added level of wear resistance.

The origins of the Cristini Group date back to the middle of the 18th century, and are deeply rooted in the traditions of the Fiorano Al Serio valley. Since the Middle Ages, this area has been actively involved in the textile industry.

In 1997 the Cristini Group built a 55,000 ft² facility in Lachute, Qc. Canada in order to establish a presence in the North American market. This facility manufactures a full line of carrier rope and rope threading systems as well as spiral fabrics for paper machine dryer sections and filtration applications.

In early 2000, Cristini also launched its Diagnostic systems division which has become the industry's leading supplier of portable and online consistency gauges FiberScan™. The Diagnostic systems division has also launched online and portable press felt porosity and moisture measurements- PermFlowDuo™ making it the only instrument able to measure moisture porosity and temperature simultaneously.

Cristini's capabilities in Paper machine clothing and carrier rope coupled with its innovative

Diagnostic instruments allow Cristini to be the only true Total Paper Machine Clothing Supplier. |